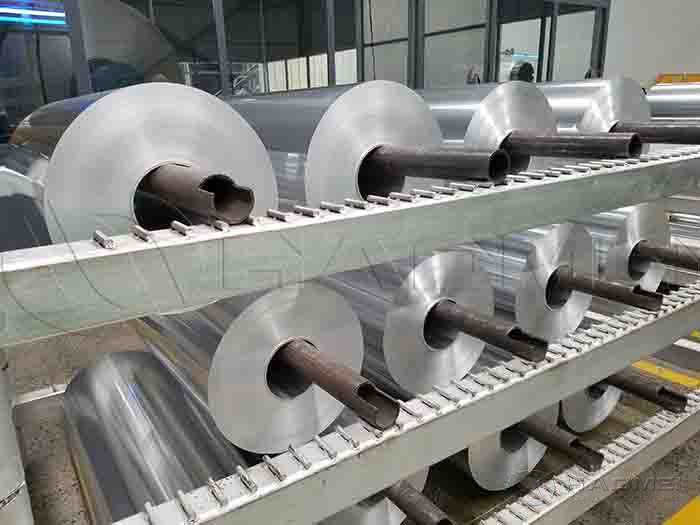

8011 Color Coated Aluminum Coil

8011 color coated aluminum foil, especially the golden aluminum foil is a main type of aluminum foil for bottle cap. How to optimize its production process to get a better comprehensive performance? Learn more.

Aluminum and aluminum alloy bottle cap material is a new type of bottle cap sealing material, which not only has the characteristics of being beautiful and easy to open, but also has the function of preventing counterfeit goods. Therefore, it has been widely used for beverage bottles, wine bottles, cosmetics bottles, medicine bottles,etc.

8011 color coated aluminum foil is a main type of aluminum foil for bottle cap, featuring good deep drawing performance, low earing rate and certain strength after baking in the lid-making process. The main alloying elements of 8011 aluminum alloy are Fe and Si, and the rest are trace impurity elements.

Its specific production process is smelting-casting-soaking-hot continuous rolling-cold rolling-intermediate annealing-cold rolling-leveling-slitting or cross-cutting-packaging. Melting and casting mainly control the content and ratio of alloying elements, the heating temperature is 500±5°C for soaking, and the holding time is not less than 20h.

The cold rolling deformation of 8011 aluminum alloy in H16 temper must be greater than 40% at least. In order to obtain an aluminum foil sheet with a small earing rate(<3%), it is necessary to adjust the process to increase the proportion of annealed texture (cubic texture) in the finished plate to offset the excess rolling texture in the aluminum sheet.

As an Al-Fe-Si alloy, the Fe/Si ratio affects the earing behavior of the 8011 aluminum foil. The earing rate of the high-silicon and low-iron alloy is very small. But with the increase of Fe content and the decrease of Si content (Fe/Si ratio increases), the deformation texture develops more strongly, which will increase the 45-degree direction earing during deep drawing of 8011 bottle cap material.

The deep drawing performance and the earing rate of the 8011 h16 have a great relationship with the soaking process, the microstructure of the hot finish rolling and the subsequent intermediate annealing process. Select a reasonable intermediate annealing process and an appropriate cold working rate to seek a balance between the cubic texture and deformation texture of the alloy while ensuring that the alloy sheet has the strength required by the standard, so as to obtain good deep drawing performance and baking resistance.

Through a large number of process test optimization and industrialized large-scale production practice verification, we have formed the production process of 8011 h16 golden aluminum sheet for bottle cap.

Haomei Aluminum has determined the chemical composition control range of 8011 aluminum alloy, and the hot final rolling temperature. At the same time, an intermediate annealing process of 320 degrees Celsius and a cold rolling processing rate of 52% compatible with the intermediate annealing process are adopted.

Using the above-mentioned optimized production process, we can obtain a 8011 golden aluminum foil with the tensile strength of 145~185MPa, elongation≧1%, earing rate ≦3% and surface roughness ≦0.4um. After baking at 210 degrees Celsius for 12 minutes and continuous baking for 5 times, the tensile strength of the 8011 aluminum foil is ≧110MPas and the elongation is ≧2%.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China