Why Is Hydrophilic Aluminum Foil Used for Air Conditioner

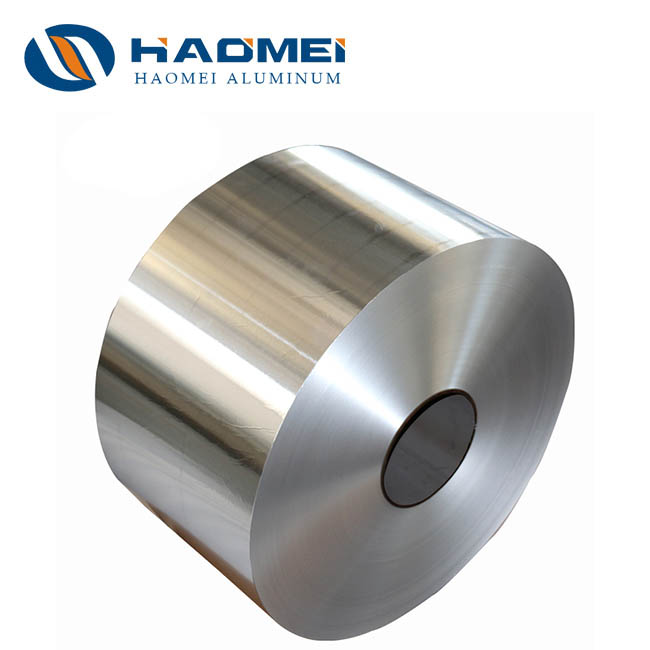

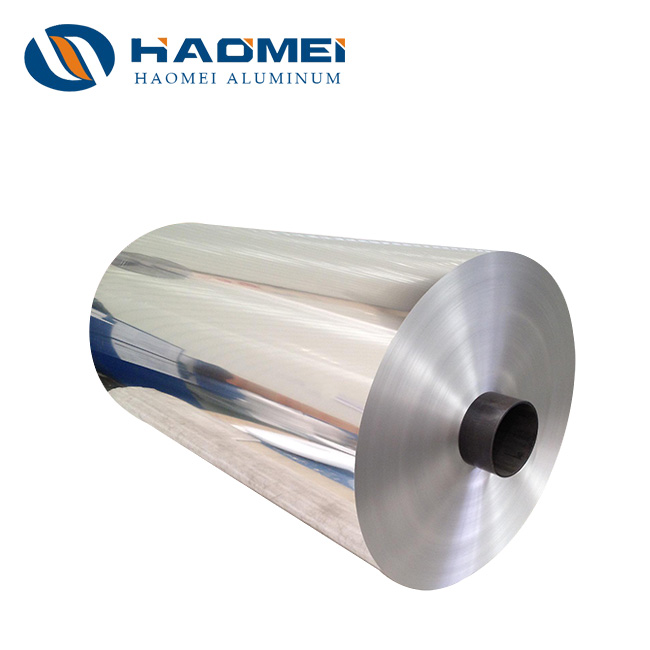

The hydrophilic aluminum foil has better heat exchange performance. Its common alloys are 1100, 1145, 3003 and 8011 aluminum ac coil. The popular colors are blue and gold aluminum foils. Learn more.

The difference between hydrophilic aluminum foil and ordinary aircon aluminum foil is that it has been surface treated - it has an additional hydrophilic layer. Since aluminum foil coated with a hydrophilic coating, its heat exchange performance is also better.

The surface of hydrophilic aluminum foil has a strong affinity for water. Condensed water spreads quickly on the fins and is not easy to form "water bridges". Therefore, its ventilation effect is good when the air conditioner is running.

The air conditioner aluminum foils are commonly used in a variety of automotive radiators, HVAC, insulation panels and air conditioning applications. 1100, 1145, 3003 and 8011 aluminum alloys are all good alloy choices due to aluminum's corrosion resistance. The colors of aircon aluminum foils are also different. Blue and gold aluminum foils are more popular.

Air conditioner aluminum foil generally chooses 3003 aluminum foil. It mainly needs to have good formability, few metallurgical defects and small anisotropy. It also requires high strength, good ductility, uniform thickness and good straightness.

The amount of aluminum foil used in air conditioners varies greatly depending on the model and power of the air conditioner. Making thinner aluminum foil can reduce the use of aluminum and reduce the cost of air conditioner radiators with the same heat exchange area.

The specific type of aluminum foil used to process heat exchange fins needs to be customized according to actual application and functional requirements. For example, whether hydrophilic or hydrophobic processes are required, and whether anti-corrosion processes are required, all need to be customized according to actual needs.

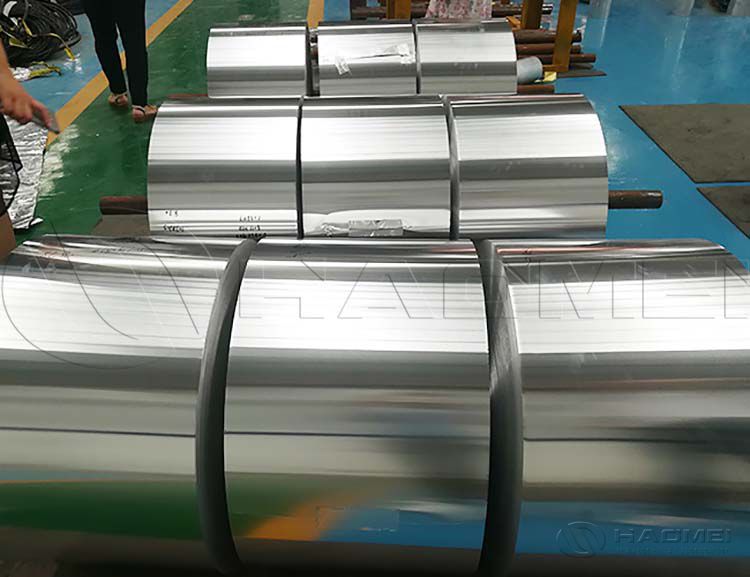

The production process of hydrophilic aluminum foil requires the aluminum ac coil to have a good shape, which is a prerequisite for the production of coated aluminum foil. The unit for measuring plate shape indicators is I. Generally, the plate shape requirements of coating production equipment are within 20-40I. If it is greater than this value, a tension straightening system needs to be added in front of the coating equipment.

Generally, the aluminum strip running route of coating equipment is long, and there are many processing steps and guide rollers. Therefore, if the tension straightening system is not equipped, once the plate shape is not good, it will easily break during operation, resulting in the failure of production.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

-

Which Medicines Are Packaged in Aluminum Foil Blister Packaging

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China