Aluminum PTP Blister Foil

The aluminum-plastic blister packaging is a main application of aluminum foil in pharmaceutical packaging. The common alloys are 8011, 8021 and 8079 aluminum foil. What is is process flow? Learn more.

The application of aluminum foil in pharmaceutical packaging includes aluminum-plastic blister packaging (PTP), strip packaging, aluminum-plastic combined bottle caps, aluminum-plastic sealing gaskets and double aluminum packaging, of which aluminum-plastic blister packaging is its main application, with moisture-proof, hygienic , safety, convenience and other advantages, thus becoming a new type of pharmaceutical packaging widely used in the world.

PTP blister foil is non-toxic, odorless and of light weight, excellent shading properties, high moisture resistance and barrier properties. PTP pharmaceutical aluminum foil base material can be divided into hard aluminum foil and soft aluminum foil. The former is mostly used for blister packaging of tablets and capsules, while the latter is generally used for outer packaging of powder and granules.

It takes very little stretch to break hard aluminum foil, so the patients can get the medicine more easily. On the other hand, if soft aluminum foil is used, more force must be applied to reach the drug because of the higher stretching force of the film. Therefore, blister packs with a covering foil made of soft aluminum are considered to be more resistant to ingestion by children.

The common alloys of aluminium blister foil are 8011, 8021 and 8079 aluminum foil. The thickness is 0.02-0.08mm. In addition to the traditional aluminum foil (PTP) for blister packaging, aluminum foil is also compounded with various plastic and paper materials as pharmaceutical packaging materials, such as cold stamping aluminum foil and tropical blister packaging aluminum foil.

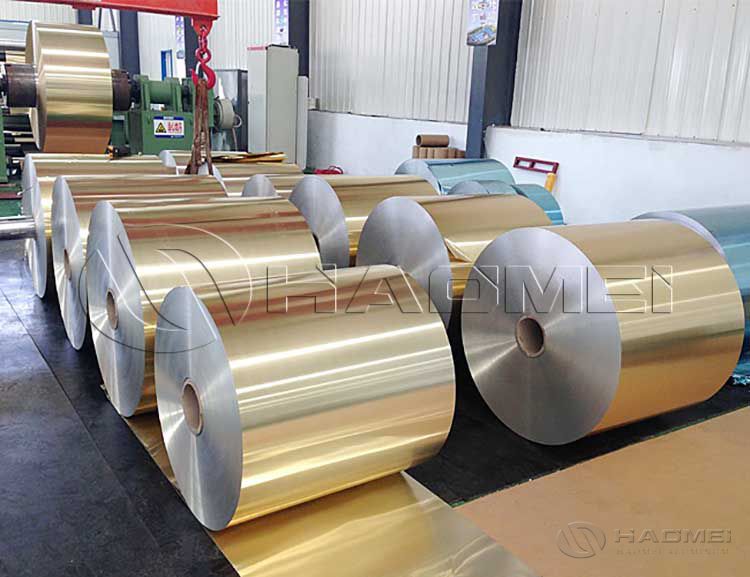

As one of the aluminium blister foil manufacturers in China, we have a mature manufacturing process. The process flow is: billet inspection→rolling→coiling→rolling→slitting→inspection, packaging and storage. The distribution of rolling passes is 0. 3 mm (H14) → 0. 145 mm → 0.1072 mm → 0. 032 mm → 2 × 0. 02 mm (H18).

Among them, the 1st and 2nd passes are rolled on the rough rolling mill (the roll crown is 0.09 mm, and the Ra value is 0.3 μm); the 3rd and 4th passes are placed in the intermediate rolling (the roll crown is 0.10 mm, Ra value 0. 15μm) rolling. The rolling speed of the 1st, 2nd and 3rd pass is 800 mPmin~1200 mPmin, and the speed of the 4th pass is 400 mPmin~450 mPmin.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

-

Which Medicines Are Packaged in Aluminum Foil Blister Packaging

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

-

What Are Aluminum Foil Uses in the Kitchen?

Food aluminum coil is a versatile kitchen helper like baking, grilling, food preservation and cookware cleaning. How can it help you deal with kitchen problems? Learn more.

Blog

Food aluminum coil is a versatile kitchen helper like baking, grilling, food preservation and cookware cleaning. How can it help you deal with kitchen problems? Learn more.

Blog

-

Aluminum Foil for Pharmaceutical Packaging

Aluminum foil pharmaceutical packaging, with its excellent barrier properties, sealing performance, and safety, has become one of the core materials for safeguarding drug quality. From common capsule and tablet packaging to specialized ointment and p

Blog

Aluminum foil pharmaceutical packaging, with its excellent barrier properties, sealing performance, and safety, has become one of the core materials for safeguarding drug quality. From common capsule and tablet packaging to specialized ointment and p

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China