What Is Specification of Aluminum Seal for Bottles

In the packaging industry, bottle sealing foil plays a crucial role, ensuring the quality of the product inside, extending its shelf life, and enhancing product safety.RequirementsGood barrier properties: This is a key characteristic of aluminum foil

In the packaging industry, bottle sealing foil plays a crucial role, ensuring the quality of the product inside, extending its shelf life, and enhancing product safety.

Requirements

Good barrier properties: This is a key characteristic of aluminum foil for bottle seals. The foil must offer excellent oxygen, moisture, and light-blocking properties. Oxygen can cause oxidation and deterioration of the product inside the bottle; moisture can dampen the product; and ultraviolet light, such as in sunlight, can trigger photochemical reactions in some products, destroying their components. High-quality aluminum foil effectively blocks these factors and maintains consistent product quality.

Reliable Sealing: The aluminum foil must form a tight and durable seal between the bottle neck and the cap. A poor seal can lead to liquid leakage; for solid products, it can allow contaminants to enter, affecting product quality. The aluminum foil must fit snugly against the bottle neck and maintain its seal under varying storage conditions, such as temperature and humidity fluctuations.

Suitable Mechanical Properties: Aluminum foil should possess a certain level of strength and flexibility. Strength ensures it resists breakage during processing, transportation, and use, while flexibility allows it to conform to various bottle opening shapes and facilitate smooth sealing.

Hygiene and Safety: For direct contact with products, aluminum foil must be non-toxic, odorless, and not release harmful substances that contaminate the product. The food, pharmaceutical, and cosmetics industries, in particular, place extremely stringent hygiene and safety requirements on aluminum foil, and the production process must adhere to relevant hygiene standards and regulations.

Excellent Processability: It facilitates various processing operations, such as stamping, forming, and laminating. It can be precisely processed into bottle caps or sealing gaskets of various shapes and sizes to meet diverse packaging needs.

Anti-counterfeiting Properties: For high-end products or industries with high anti-counterfeiting requirements, aluminum foil can be equipped with special anti-counterfeiting features, such as specialized printing processes and anti-counterfeiting markings. This prevents counterfeiting and protects brand and consumer rights.

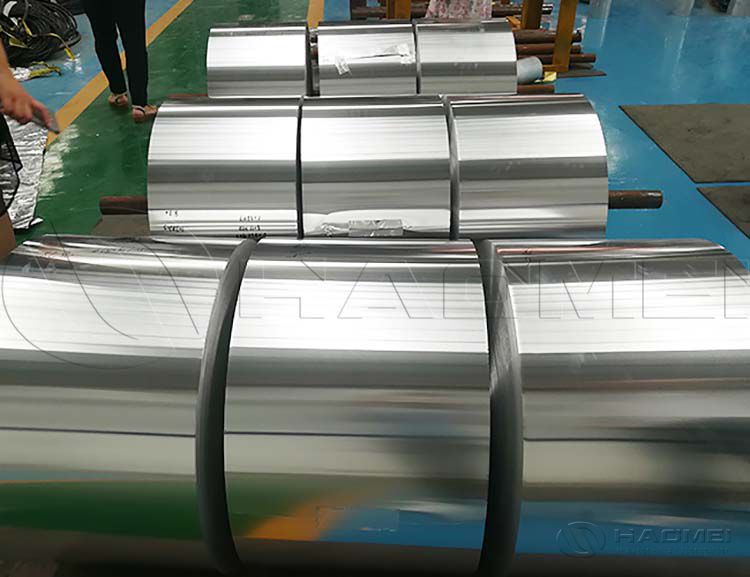

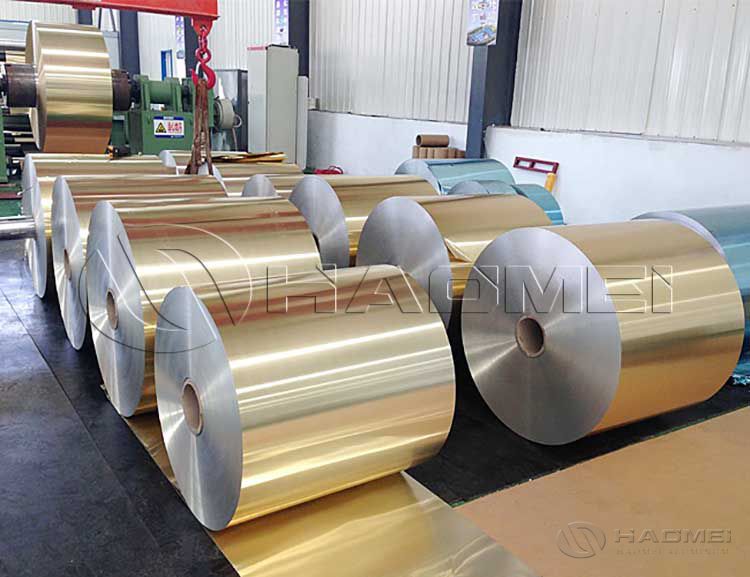

Common Specifications of aluminum foil for bottle seal

Thickness: Common thicknesses range from 0.15 to 0.5mm. For example, aluminum oil used for wine and beverage bottle caps typically has a thickness of 0.2 to 0.3mm. Aluminum foil jumbo roll used for pharmaceutical bottle caps generally has a thickness of 0.15 to 0.27mm. Different products have different thickness requirements.

Thinner foil is suitable for lightweight packaging and reduces costs, while thicker foil is used for products requiring high barrier properties and strength. Thickness tolerances are typically controlled within ±0.01% to ensure consistent product quality.

Width: Widths vary widely, ranging from 330 to 1000mm or even wider. Common widths include 449 to 796mm. The width selection depends on the size of the bottle cap or closure gasket, as well as the specifications of the production equipment. The key is to ensure that the aluminum seal for bottles can meet the production requirements of different product sizes while also balancing production efficiency and material utilization.

Alloy Grade: Common alloy grades include 8011, 1235, 1070, 1060, 5052, 3105, and 3104. 8011 aluminum foil is widely used, such as bottle cap packaging for the alcoholic beverage, cosmetics, and pharmaceutical industries.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China