Plain or Hydrophilic Aluminum Coil for AC

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydrophilic aluminum foil are the two main types of aluminum foil used in the air conditioning industry. These two types differ significantly in production processes, performance, and market applications.

Plain aluminum foil

Plain aluminum foil refers to aluminum foil that undergoes a rolling and annealing process, without any coating or special surface treatment. Its production process is relatively simple, requiring no additional coating steps, resulting in lower production costs. In the early days of the air conditioning industry, plain aluminum foil was widely used in various air conditioner heat exchangers and is still used in some cost-conscious applications, such as the manufacture of heat exchangers for mid- and low-end fixed-frequency air conditioners sold domestically, window air conditioners, and some automotive air conditioners.

From a performance perspective, plain aluminum foil has significant limitations. Due to the lack of a protective coating, its corrosion resistance is relatively weak. During operation, condensate inside the heat exchanger and impurities in the air directly contact the aluminum foil surface, potentially leading to oxidation and rust, which in turn affects heat exchange efficiency. Condensate condensing on the surface of plain aluminum foil can easily form droplets, even forming "water bridges" between the heat exchanger fins. This can hinder air circulation, further reducing the heat exchange performance of the heat exchanger and increasing air conditioner energy consumption.

Hydrophilic aluminum foil

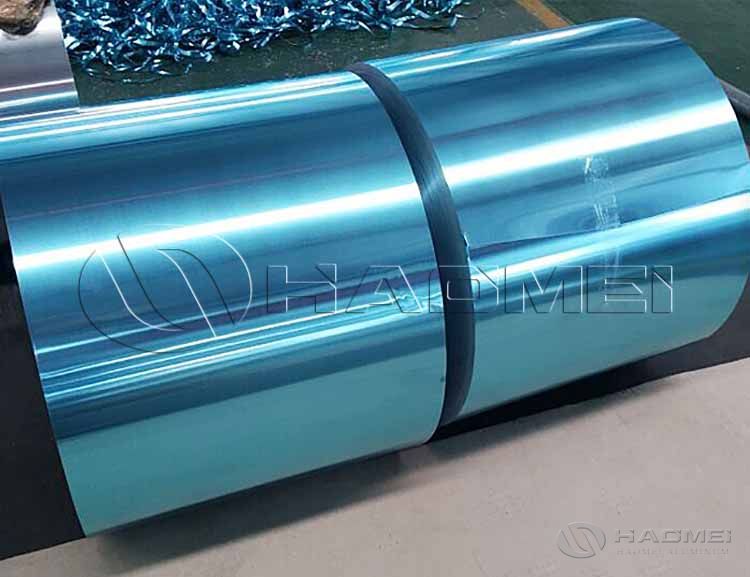

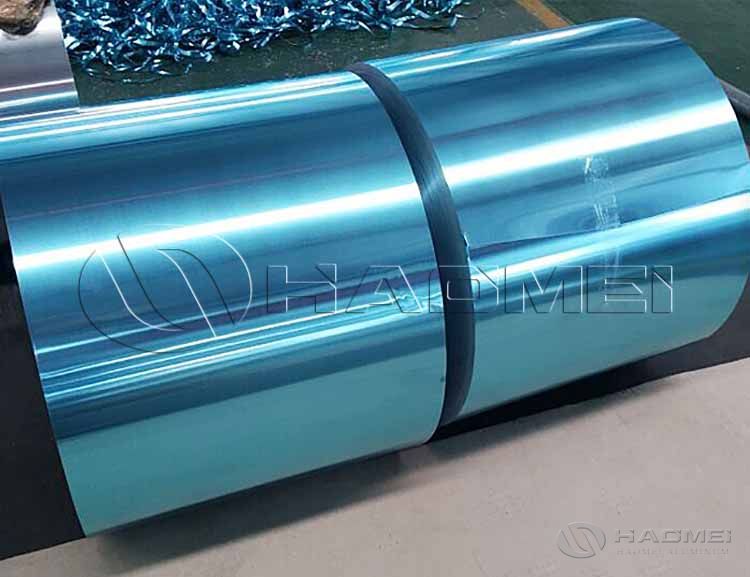

Hydrophilic aluminum foil is a modified aluminum foil product made by applying an anti-corrosion inorganic coating and a hydrophilic organic coating to the surface of plain aluminum foil, followed by a special curing process. Due to its superior performance, hydrophilic aluminum fin has become the mainstream choice in the current air conditioner aluminum foil market.

According to industry statistics, it accounts for over 80% of total air conditioner aluminum foil usage. Hydrophilic aluminum foil is widely used in inverter air conditioners, air conditioners for export, and mid-to-high-end fixed-frequency air conditioners, becoming a core material for air conditioner heat exchanger manufacturing.

The core advantages of hydrophilic aluminum foil are primarily reflected in the following four aspects:

Improved heat exchange efficiency and reduced energy consumption: The surface of hydrophilic aluminum foil has strong hydrophilic properties, allowing condensed water to quickly spread out as a film rather than aggregate into droplets, then flow smoothly down the foil surface. This feature prevents the "water bridge" phenomenon that hinders air circulation, improving the heat exchange efficiency of the heat exchanger by approximately 5% compared to plain aluminum foil. For the same cooling/heating requirements, air conditioners using hydrophilic aluminum foil can reduce energy consumption, significantly lowering users' electricity bills over the long term.

Enhanced corrosion resistance and extended service life: The anti-corrosion coating effectively isolates condensate and corrosive substances in the air from the aluminum foil substrate, preventing oxidation and rust. Testing has shown that heat exchangers using hydrophilic aluminum foil have a service life 3-5 years longer than plain aluminum foil, reducing air conditioner repair costs due to heat exchanger failure.

Inhibits mold growth and protects indoor air quality: The coating on the hydrophilic aluminum foil has antibacterial properties, inhibiting the growth of bacteria and mold on the foil surface. This prevents mold metabolites from entering the air with airflow and causing odor during air conditioning operation, while also reducing mold contamination of indoor air, meeting user needs for a healthy environment.

Core Drivers of Market Share Difference

Hydrophilic aluminum foil's market share exceeding 80% stems from its performance closely aligned with market demand and industry trends. This can be analyzed from three perspectives:

Upgrading Consumer Demand: As living standards improve, consumers are no longer solely focused on price when purchasing air conditioners; they are increasingly considering energy efficiency ratings, service life, and health features. The advantages of hydrophilic aluminum foil in energy saving, durability, and antibacterial properties perfectly match consumer demand for high-quality air conditioners, becoming the core driver of its growing market share.

Manufacturer Competition and the Need for Product Upgrades: With intensifying competition in the air conditioner industry, manufacturers need to differentiate themselves by improving product performance. Using hydrophilic aluminum foil can significantly improve the core performance of air conditioners, helping them achieve advantages in key indicators such as energy efficiency labeling and service life. Especially in the high-end market and export sectors, hydrophilic aluminum foil has become an essential choice for manufacturers to enhance product value and meet international market standards.

Industry policies and environmental trends have guided: In recent years, national energy efficiency standards for air conditioners have continued to rise, while environmental awareness has also deepened within the industry. Hydrophilic aluminum foil improves heat exchange efficiency and reduces air conditioner energy consumption. This complies with national energy efficiency standards and energy conservation and environmental protection policies, making it a key material choice for manufacturers to meet these requirements and respond to environmental trends. Welcome to inquire aluminium coil for ac price from us directly.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

-

Which Medicines Are Packaged in Aluminum Foil Blister Packaging

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China