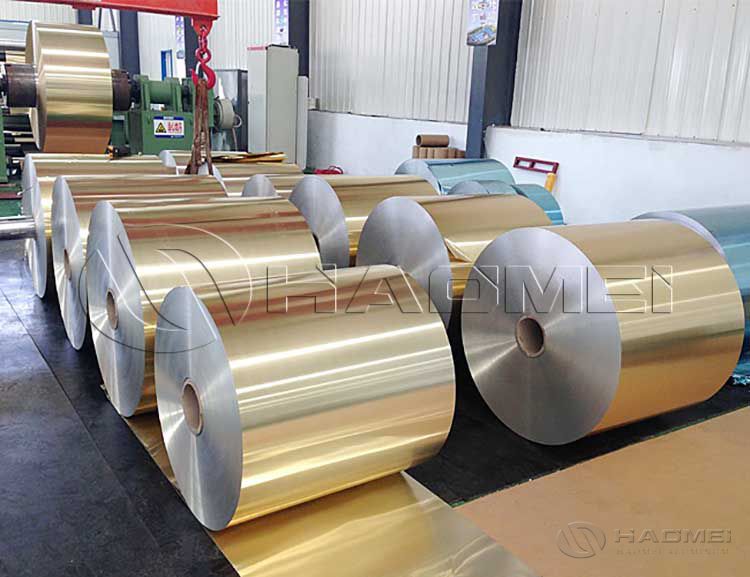

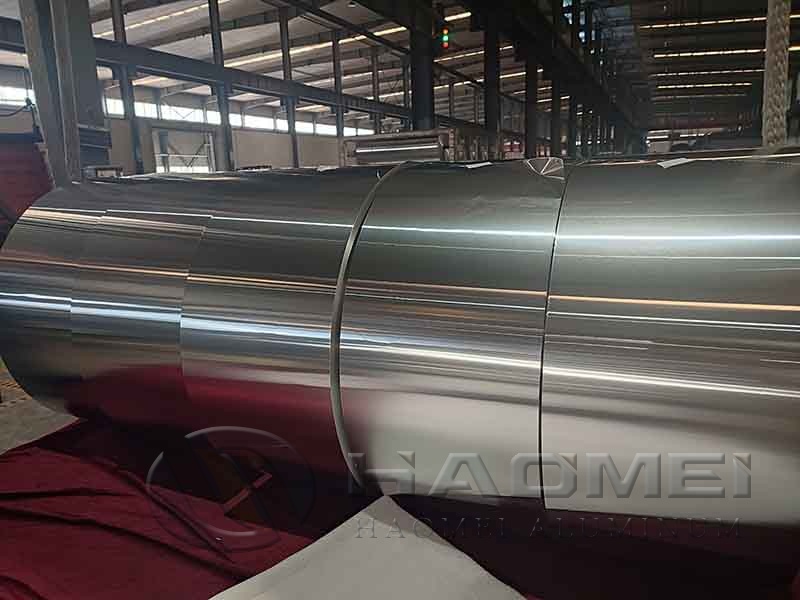

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properties, and processing flexibility, has become a core raw material for these components.

Core Aluminum Foil Types and Corresponding Alloys

Pure Aluminum Foil

Pure aluminum foil is characterized by its high thermal conductivity and excellent plasticity. It primarily uses 1000 series alloys, with 1050 and 1060 alloys being the most widely used. These alloys have an aluminum content of over 99.5%, a thermal conductivity of up to 237 W/(m·K), enabling rapid heat conduction. They also possess excellent stamping and bending properties, allowing for ultra-thin specifications of 0.08-0.15mm, maximizing the heat dissipation surface area within limited space.

In the manufacture of fins for household air conditioners and small electronic devices, 1050/1060 pure aluminum foil is the mainstream choice. Through precision stamping processes, corrugated and serrated fins can be produced. Combined with hydrophilic coating treatment, this reduces condensation residue and lowers wind resistance and noise.

Actual test data shows that air conditioner fins using this type of aluminum foil can increase the heat exchange area per unit volume by 40%, and improve the overall energy efficiency ratio (EER) by 15% compared to traditional materials. Its naturally formed dense alumina film can also effectively resist corrosion in humid environments, extending the service life of the heat exchanger.

Aluminum Alloy Foil

For complex operating conditions in industrial equipment, automobiles, and other applications, the strength and temperature resistance of pure aluminum foil alone are insufficient. 3000 series, 5000 series, and brazing-specific aluminum alloy foils have emerged, achieving performance upgrades through alloy element optimization.

3003 aluminum alloy foil is a representative finstock aluminum foil. With the addition of manganese to pure aluminum, its strength is increased by more than 30% compared to the 1000 series, while retaining good thermal conductivity and processability. It can adapt to high-speed stamping processes, with less die wear, making it suitable for mass production. This type of aluminum foil is commonly used in heat exchanger fins of commercial air conditioners and industrial frequency converters, maintaining structural stability within a temperature range of -40℃ to 80℃ and withstanding frequent thermal cycles without deformation.

5052 alloy aluminum foil is known for its high corrosion resistance and mechanical properties. Its magnesium-containing composition gives it a tensile strength exceeding 280 MPa and an elongation of 12%-15%, making it particularly suitable for explosion-proof fins in the thermal management systems of new energy vehicle batteries. In simulated battery thermal runaway experiments, 5052 alloy aluminum foil can withstand temperatures up to 1250℃ for 30 minutes without cracking, buying crucial time for occupants to escape. It is currently supplied to leading power battery companies such as CATL and BYD.

Brazing Aluminum Foil

Components such as automotive engine radiators and air conditioning condensers require extremely high connection strength and high-temperature resistance. Brazing aluminum foil has become a core material, primarily using 4000 series (aluminum-silicon alloy) as the filler layer, combined with 3003 or 6063 alloy as the core layer, forming a composite structure. This type of aluminum foil needs to possess good anti-sagging properties, resisting gravity and thermal stress during high-temperature brazing to maintain shape stability, while ensuring the sealing and thermal conductivity of the brazed joint.

By optimizing the proportions of elements such as Fe, Si, and Mn, brazed aluminum foil can achieve a balance between mechanical and thermal conductivity. For example, when the Fe content is controlled at around 0.3%, the Si content at 1.0%, and the Mn content at 1.5-2.0%, the α(Al(FeMn)Si) phase formed in the alloy microstructure significantly improves anti-sagging performance, meeting the stringent operating requirements of automotive heat exchangers. Automotive heat exchangers manufactured using brazed aluminum foil can be 20%-40% lighter than traditional copper products, contributing to vehicle lightweighting and energy conservation.

Surface Treatment and Process Enhancement of Aluminum Foil

Besides the inherent properties of the alloy, surface treatment processes are crucial for heat exchanger foil to achieve optimal performance. Hydrophilic coating is a standard process for finned aluminum foil. By forming a nano-scale diatomaceous earth + organosilicon composite film on the aluminum foil surface, the water contact angle can be reduced from 60° to 15°, increasing hydrophilicity by 4 times. This allows condensate to slide off quickly, improving drainage efficiency by 60%, while simultaneously reducing bacterial growth and corrosion risks.

For high-end applications, processes such as anodizing and graphene coating can further optimize performance: anodizing generates a thicker oxide layer, enhancing corrosion resistance and surface smoothness; graphene coating improves heat transfer efficiency, and black coatings increase radiative heat dissipation.

In data center cooling systems, combining coated aluminum foil fins with smooth aluminum foil can increase heat dissipation area utilization by 35%, reduce the PUE value from 1.6 to 1.3, and save over 2 million kWh of electricity annually.

Application Scenarios Expanded

The application of aluminum foil in fins and heat exchangers has penetrated into multiple fields, forming differentiated solutions: In the field of electronic equipment, 0.08mm ultra-thin pure aluminum foil combined with micro-fin structures can reduce the volume of heat sinks by 40%, adapting to the high-density heat dissipation requirements of 5G base stations and servers.

In the automotive field, the combination of brazed aluminum foil and explosion-proof aluminum foil can meet the high-temperature requirements of engine heat dissipation while ensuring battery pack safety; in the industrial field, customized alloy aluminum foil can be adapted to the extreme operating conditions of equipment such as frequency converters and inverters, achieving efficient heat dissipation and long-term stable operation.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Price Comparison Of Different Types Of Aluminum Foils

Aluminum foil jumbo roll is a versatile metallic material used in life, industry and medicine. Learn about the price ranges of household, air conditioning and pharmaceutical-grade aluminum foil, and the key factors causing their price differences. Blog

-

Aluminum Foil Specification for Food Container

Container aluminum foil for trays and pans: learn alloy choices, tempers, thickness, coatings, forming performance, and quality checks for stable production.

Blog

Container aluminum foil for trays and pans: learn alloy choices, tempers, thickness, coatings, forming performance, and quality checks for stable production.

Blog

-

2026 China Aluminum Foil Export Price Forecast

2026 China aluminum foil jumbo roll export price forecast: Overall fluctuation with range-bound operation ($4100-$4400/ton), analyzing core supports, constraints & variables, offering references for industry practitioners & foreign trade enterprises.

Blog

2026 China aluminum foil jumbo roll export price forecast: Overall fluctuation with range-bound operation ($4100-$4400/ton), analyzing core supports, constraints & variables, offering references for industry practitioners & foreign trade enterprises.

Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China