What Is Aluminum Foil Electrical Conductivity

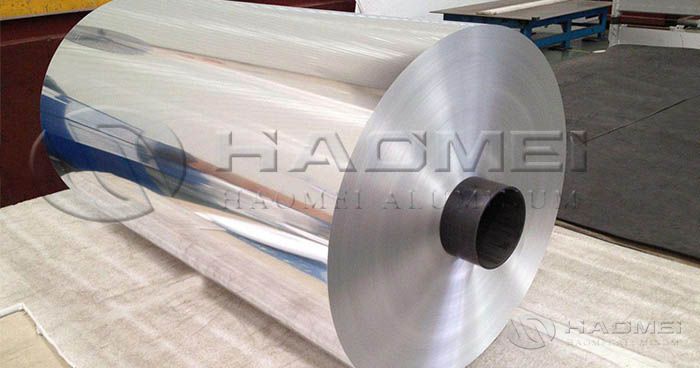

In the industrial sector, the aluminum foil jumbo roll, thanks to its advantages such as lightweight, corrosion resistance, and easy processing, has become a fixture in the electronics, energy, and packaging industries. Electrical conductivity, as a

In the industrial sector, the aluminum foil jumbo roll, thanks to its advantages such as lightweight, corrosion resistance, and easy processing, has become a fixture in the electronics, energy, and packaging industries. Electrical conductivity, as a core metric for measuring a material's ability to conduct electricity, directly determines the value of aluminum foil in electrical conductivity-related applications.

To determine the electrical conductivity of aluminum foil, a reference standard is first needed. Industry typically uses the International Annealed Copper Standard (IACS), defining the conductivity of annealed pure copper as 100% IACS.

According to data, the electrical conductivity of pure aluminum (99.99% purity or above) is approximately 60%-65% IACS (35-38 S/m at 20°C). While this is significantly lower than pure copper, it is significantly higher than most alloy materials (for example, ordinary steel has a conductivity of only about 3%-5% IACS, and stainless steel is even lower). The conductivity of battery aluminum foil in actual use will fluctuate slightly due to processing techniques (such as rolling and annealing) and alloy composition:

Annealed aluminum foil: After high-temperature annealing, the aluminum foil's internal grains become more uniform, internal stress is reduced, and its conductivity approaches that of pure aluminum, typically reaching 58%-63% IACS.

Hard aluminum foil: Unannealed or lightly processed aluminum foil experiences increased resistance due to lattice distortion, resulting in a 10%-15% decrease in conductivity, typically to 45%-55% IACS.

Notably, aluminum's density is only about one-third that of copper. When calculated based on "conductivity per unit weight," aluminum's advantages are further highlighted—at the same weight, aluminum's conductivity is approximately twice that of copper.

The electrical conductivity of aluminum foil is essentially determined by its purity and alloying element content. Alloying elements (such as magnesium, silicon, manganese, and copper) form solid solutions or intermetallic compounds with aluminum, hindering the directional movement of electrons and thus reducing conductivity. Therefore, high-conductivity aluminum foil is almost exclusively found in pure and low-alloy aluminum series, such as 1000 aluminum foils.

1235 aluminum foil: aluminum content is approximately 99.35%, iron content is 0.3%-0.6%, and silicon content is ≤0.12%. Its electrical conductivity is approximately 58%-62% IACS, and it also exhibits good ductility.

1100 aluminum foil: Aluminum content ≥99.0%, iron + silicon content ≤1.0%, conductivity approximately 55%-58% IACS. Compared to 1235, it offers better processing performance and a lower price. It is commonly used in cost-sensitive applications such as conductive gaskets for low-voltage electrical appliances and electrolytic capacitor casings, where conductivity requirements are slightly lower.

1060 aluminum foil: With an aluminum content of ≥99.6% and extremely low impurity levels, it has a conductivity of 62%-65% IACS, making it one of the most conductive grades in the 1 series. However, this high purity also results in lower strength and increased deformation. It is primarily used in high-end applications such as conductive connections for precision electronic components and as laboratory electrode materials.

Lithium battery current collectors are a core application for high-conductivity aluminum foil. In lithium-ion batteries, aluminum foil is used as the current collector for the positive electrode (copper foil for the negative electrode). With a conductivity of 58%-62% IACS, 1235 battery aluminum foil efficiently collects the current generated by the positive electrode and transmits it to the external circuit. Currently, a new energy vehicle's power battery consumes approximately 20-50 kilograms of aluminum foil. As electric vehicle penetration increases, demand for highly conductive aluminum foil continues to grow.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Price Comparison Of Different Types Of Aluminum Foils

Aluminum foil jumbo roll is a versatile metallic material used in life, industry and medicine. Learn about the price ranges of household, air conditioning and pharmaceutical-grade aluminum foil, and the key factors causing their price differences.

Blog

Aluminum foil jumbo roll is a versatile metallic material used in life, industry and medicine. Learn about the price ranges of household, air conditioning and pharmaceutical-grade aluminum foil, and the key factors causing their price differences.

Blog

-

Aluminum Foil Specification for Food Container

Container aluminum foil for trays and pans: learn alloy choices, tempers, thickness, coatings, forming performance, and quality checks for stable production.

Blog

Container aluminum foil for trays and pans: learn alloy choices, tempers, thickness, coatings, forming performance, and quality checks for stable production.

Blog

-

2026 China Aluminum Foil Export Price Forecast

2026 China aluminum foil jumbo roll export price forecast: Overall fluctuation with range-bound operation ($4100-$4400/ton), analyzing core supports, constraints & variables, offering references for industry practitioners & foreign trade enterprises.

Blog

2026 China aluminum foil jumbo roll export price forecast: Overall fluctuation with range-bound operation ($4100-$4400/ton), analyzing core supports, constraints & variables, offering references for industry practitioners & foreign trade enterprises.

Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China