1050 VS1060 Aluminum Foil

Composition Purity 1050 Aluminum Foil: Aluminum content is ≥99.5%, belonging to basic high-purity pure aluminum, with no additional alloying elements added, resulting in a simpler composition. 1060 Aluminium Foil: Aluminum content is ≥

Composition Purity

1050 Aluminum Foil: Aluminum content is ≥99.5%, belonging to basic high-purity pure aluminum, with no additional alloying elements added, resulting in a simpler composition.

1060 Aluminium Foil: Aluminum content is ≥99.6%, purity slightly higher than 1050 alloy, and it contains trace amounts of copper, achieving performance upgrades through minor composition adjustments.

Mechanical and Core Properties

1050 Aluminum Foil: Tensile strength range is 70-130MPa, with moderate ductility; its core advantage is controllable cost, balanced electrical and thermal conductivity, meeting basic application requirements.

1060 Aluminum Foil: It has higher upper limit of tensile strength (70-180MPa), yield strength significantly better than 1050; its core advantages are superior formability, stronger corrosion resistance, and excellent surface smoothness and quality, suitable for high-requirement applications.

Production Process

1050 Aluminum Foil: It requires no complex alloy formulation required, simplifying the production process, lower technological threshold, suitable for large-scale, low-cost mass production.

1060 Aluminum Foil: It requires additional heat treatment, stricter control over thickness tolerances, more refined production processes, and relatively higher costs.

Core Application Areas

1050 Aluminum Foil: It focuses on basic, essential applications, such as electrolytic capacitor substrates (0.006-0.2mm), aluminum can bodies/ordinary aluminum foil bags (0.01-0.1mm), automotive heat shields (0.8mm), and small chemical storage tanks (5-20mm), emphasizing cost-effectiveness.

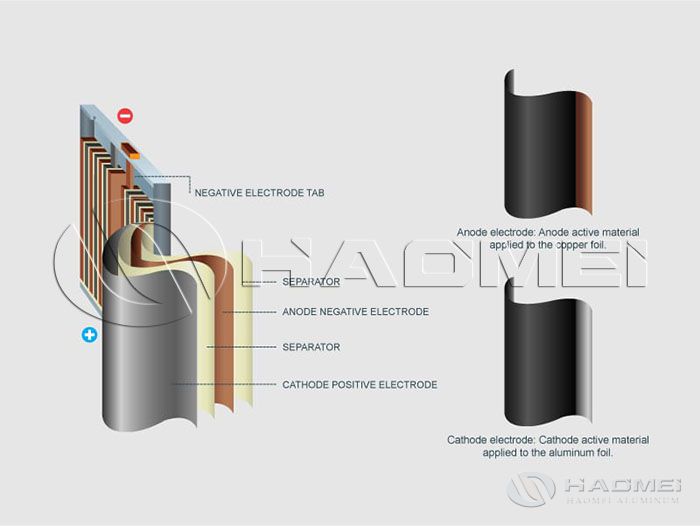

1060 Aluminum Foil: It primarily targets mid-to-high-end applications, such as precision packaging for cosmetics/pharmaceuticals (relying on ductility and barrier properties), lithium battery current collectors (requiring both conductivity and heat dissipation), and building energy-saving insulation rolls (low radiation + waterproofing), emphasizing performance adaptability.

Market Landscape

In the global lithium-ion battery aluminum foil market, there is a clear market share gap between 1060 and 1050 aluminum foil:

Data from 2023 shows that 1060 aluminum foil ranked second with a 30% share, and its market size is projected to reach $491 million in 2025 and surge to $2.73 billion in 2034, representing a CAGR of 20.8%; 1050 aluminum foil follows closely with a 20% share, and its market size grew from $327 million to $1.815 billion during the same period, a growth rate of 20.6%.

This gap stems from the difference in value of application scenarios: 1060 aluminum foil dominates the new energy and high-end electronics market, with demand surging due to the global popularization of electric vehicles; 1050 aluminum foil covers traditional packaging and general industrial fields, where market demand is stable but growth is relatively slow.

Selection Guide

For scenarios such as food packaging and general cable shielding where performance requirements are not extreme, the aluminium 1050 price advantage is significant.

In fields such as lithium batteries, precision electronics, and high-end packaging, 1060 alloy’s superior formability and stability are paramount.

For thickness requirements, 1060 aluminum foil is recommended for ultra-thin foils (<10μm), while for standard thicknesses (10-12μm), either 1050 or 1060 foil can be chosen based on specific needs.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China