Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

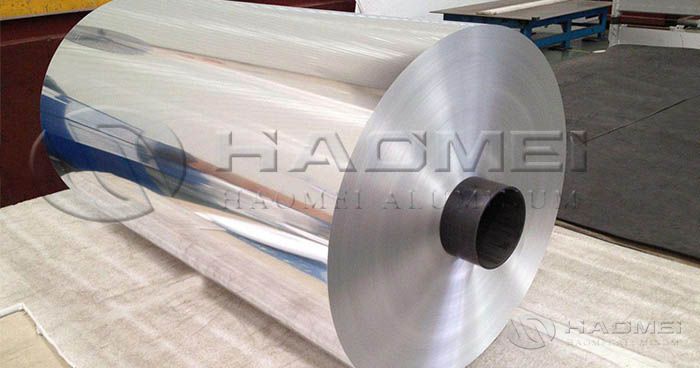

Among the many basic materials in industrial production, industrial aluminum foil, with its excellent properties such as lightness, thinness, corrosion resistance, good thermal conductivity, and strong barrier properties, has become an indispensable "all-rounder" in many fields such as packaging, electronics, automobiles, and construction. The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost, and is a key factor affecting its application effectiveness.

Thickness Grading and Core Relationships of Industrial Aluminum Foil

The thickness range of industrial aluminum foil is typically between 0.002mm and 0.5mm. The industry commonly categorizes it by thickness into four types: ultra-thin foil, thin foil, medium-thick foil, and thicker foil. The core characteristics of aluminum foil differ significantly across these thickness ranges:

- Ultra-thin foil (0.002mm-0.009mm): Extremely thin and light, with excellent flexibility and high adhesion, but lower mechanical strength and susceptibility to breakage. Primarily used in high-precision, high-requirement applications.

- Thin foil (0.01mm-0.05mm): Balances thinness and strength, offering excellent barrier properties and strong processing adaptability. One of the most widely used thickness ranges.

- Medium-thick foil (0.05mm-0.2mm): Higher strength, good puncture resistance and formability. Can be used directly in rigid or semi-rigid applications, with relatively moderate cost.

- Thicker foil (0.2mm-0.5mm): High strength and rigidity, able to withstand certain pressure and machining, suitable for structural or load-bearing applications. As an aluminum foil factory, Haomei Aluminum can customize aluminum foil thickness according to your need.

Thickness Requirements Table

1. Packaging

Barrier properties preferred, thickness adapted to scenario complexity. Packaging is the primary application area for industrial aluminum foil, covering sub-scenarios such as food, pharmaceuticals, and industrial consumables. Core requirements are moisture protection, light protection, sealing, and sterility. Thickness selection must consider both packaging form and protection requirements:

- Food packaging: Divided into flexible packaging and rigid packaging. For flexible packaging such as individual candy and chocolate wrappers, and yogurt caps, a balance between barrier properties and flexibility is required. A thickness of 0.006mm-0.015mm (ultra-thin foil/thin foil) is recommended. Beer bottle sealing foil commonly uses 0.009mm-0.015mm 8011 aluminum foil, which provides both sealing and easy opening.

For rigid packaging such as aluminum foil food containers and baking containers, formability and puncture resistance are required. A thickness of 0.03mm-0.12mm (thin foil/medium-thick foil) is recommended, commonly using 3003 and 8011 alloys, which can withstand high-temperature baking and impacts during transportation.

- Pharmaceutical Packaging: Extremely high requirements for sterility, moisture resistance, and safety. Core products are PTP pharmaceutical aluminum foil (blister packaging) and bottle cap sealing foil. PTP aluminum foil needs to balance tearability and barrier properties, with a recommended thickness of 0.012mm-0.026mm (thin foil).

Commonly used alloys are 8011 and 8021, and it must pass microbial limit testing and heavy metal leaching tests. Aluminum-aluminum pharmaceutical foil (thickened pharmaceutical foil) is used for pharmaceutical packaging with higher requirements, and its thickness can reach 0.09mm-0.15mm (medium-thick foil).

- Industrial consumable packaging: such as cable packaging and equipment moisture-proof packaging, requires a certain level of protection and breakage resistance. A thickness of 0.02mm-0.05mm (thin foil) is recommended, commonly using 1235 and 1100 alloys, which can effectively isolate moisture and impurities.

2. Electronics Field

The electronics field has extremely high requirements for the purity and thickness uniformity of aluminum foil. The core requirements are conductivity, insulation, and shielding. Thickness deviation directly affects the performance stability of electronic components. In some applications, a thickness deviation of ≤±4% (high-precision standard) is even required.

- Electrolytic Capacitors: This is a core application in the electronics field. The aluminum foil needs to undergo etching and formation treatments to increase the surface area and improve capacitor performance. The cathode foil thickness is 0.018mm-0.050mm (thin foil), while the capacitor foil (used for the anode) is even thinner, only 0.002mm-0.0045mm (ultra-thin foil), commonly using high-purity 1235 alloy with a purity ≥99.6%.

- Power Batteries: As the positive electrode current collector in lithium-ion batteries, aluminum foil needs to balance lightweight design and conductivity. Thickness directly affects battery energy density; a thickness ≤0.012mm (ultra-thin foil) is recommended. Currently, the mainstream product in the industry is 0.008mm-0.012mm, which effectively reduces battery weight and improves range.

- Electromagnetic Shielding: Used for circuit shielding in high-frequency electronic equipment to prevent signal interference. A thickness of 0.01mm-0.03mm (thin foil) is recommended. The excellent conductivity of aluminum foil forms the shielding layer; the higher the adhesion, the better the shielding effect.

3. Automotive Sector

With the advancement of automotive lightweight trends, the application of aluminum foil in the automotive industry continues to increase. The core requirements are weight reduction, thermal conductivity, and sound and heat insulation. Thickness selection must balance strength and lightweight goals, typically reducing overall vehicle weight by 5%-10%:

- Heat Exchange Systems: Including automotive radiators, condensers, evaporators, etc., requiring good thermal conductivity. A thickness of 0.045mm-0.08mm (medium-thick foil) is recommended, commonly using 1100 and 8011 alloys. Currently, the aluminum content of automotive radiators has reached 40%, and annual demand continues to grow.

- Sound and Heat Insulation Layers: Used for interior sound insulation and engine compartment heat insulation, requiring sufficient strength and heat insulation. A thickness of 0.1mm-0.2mm (medium-thick foil) is recommended. Folding can create an air layer to improve heat insulation while withstanding the high-temperature environment of the engine.

- Battery Pack Components: For separators and cooling system fins in new energy vehicle battery packs, a thickness of 0.03mm-0.08mm (thin/medium-thick foil) is recommended. These components must meet both insulation and thermal conductivity requirements to ensure safe and stable battery pack operation.

4. Construction Sector

Aluminum foil in the construction sector is mainly used for thermal insulation and decoration. The core requirements are thermal insulation, weather resistance, and aesthetics. Thickness selection must consider the usage environment and structural requirements:

- Thermal Insulation Materials: Such as aluminum foil glass wool and aluminum foil corrugated cardboard, used as insulation layers for walls and roofs. Utilizing the high reflectivity of aluminum foil (up to 90%), heat transfer is reduced. A thickness of 0.04mm-0.1mm (thin/medium-thick foil) is recommended, effectively reducing building energy consumption.

- Decorative materials: Such as brushed aluminum foil sheets and composite aluminum foil films, used for wall and ceiling decoration in commercial spaces. These require a certain degree of rigidity and corrosion resistance. A thickness of 0.1mm-0.3mm (medium-thick foil/relatively thick foil) is recommended, combining a metallic texture with durability.

- Sound insulation materials: Such as honeycomb aluminum panel core materials. These require good compressive strength and sound insulation. A thickness of 0.05mm-0.15mm (medium-thick foil) is recommended. When combined with an outer aluminum panel, they can solve the problem of traditional ceilings being prone to deformation.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more. Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

-

Which Medicines Are Packaged in Aluminum Foil Blister Packaging

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China