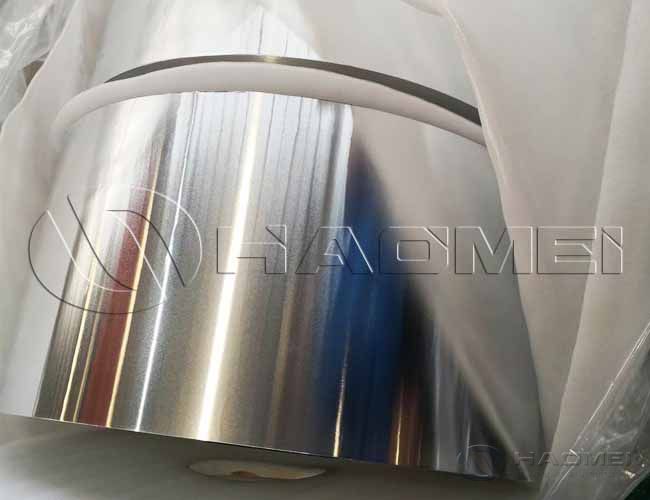

Alu Base Foil for Medicine Packaging

Blister packaging is a commonly used packaging form for medicines. The two common alu base foil alloys are 8011 and 8021. What are their properties? And How to optimize their performance. Learn more.

Blister packaging is a commonly used packaging form for pharmaceutical products. The two parts of the hard sheet and the aluminium foil are heat-sealed together to form a closed space that can accommodate medicines. In view of the fact that the blisters of the blister pack are not connected, the damage of one of the blisters will not affect the sealing of the other blisters, so whether it is during the storage of the drug or after taking part of the drug, blister packaging has a good protective effect on medicines.

For foil medicine packaging, the quality is largely reflected in the heat-sealing strength of the product. Aluminum foil is the carrier of the adhesive layer, and its quality has a great impact on the heat-sealing strength of the product. Especially the surface oil of the original aluminum foil can weaken the adhesion between the adhesive layer agent and the original aluminum foil. If there is oil on the surface of the alu base foil and the surface tension is lower than 3.1×10-2μm, it will be difficult to achieve the ideal heat sealing strength, so the quality of the original aluminum foil must be strictly controlled.

The common ptp aluminum foil alloys are 8011 and 8021. The surface of 8011 aluminum foil is clean, of uniform color and free of spots and pinholes. I has strong mechanical properties, high blast resistance, strong puncture and tear resistance. Aluminum foil after compounding, printing and gluing is widely used as packaging material.

8021 aluminum foil plays a key role as a barrier material. 8021 aluminum foil has excellent electrical conductivity and shading properties, high moisture resistance, gas barrier and taste retention, which can block any gas, water vapor and light, and can effectively protect the packaged objects.

The pharmaceutical blister packaging made of it has the advantages of good protection performance, small storage space, low cost, light weight, and easy to carry, and is one of the widely used pharmaceutical packaging forms at present.

According to their different tempers of alu alu base foil, they are used on different drug packages. The O state is commonly used in the packaging of capsules, tablets, etc., and the H18 state is relatively hard and is used in the packaging of granule drugs. Initially, simple packages such as plastic and paper were used in drug packaging, but these packages are not easy to preserve, and are easy to destroy the ingredients of the drug, which greatly reduces the efficacy of the drug. Nowadays, aluminum foil medicine packaging is a good solution to the above problems for medicine packaging.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

-

Which Medicines Are Packaged in Aluminum Foil Blister Packaging

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China