Blister Packaging: Aluminum foil and PVDC PVC

Opening a medicine box, the pills and capsules encased in transparent "bubbles" always give a sense of reassurance; opening a snack bag, individually wrapped candies and nuts are often hidden in similar packaging. This packaging format, which co

Opening a medicine box, the pills and capsules encased in transparent "bubbles" always give a sense of reassurance; opening a snack bag, individually wrapped candies and nuts are often hidden in similar packaging. This packaging format, which combines protection and display functions, is the familiar blister packaging.

The structure of blister packaging seems simple, but it is actually a precise combination of a "blister layer + sealing layer." The blister layer is responsible for shaping and supporting the product, giving it its own independent "small space".

The sealing layer is responsible for sealing and protecting it, isolating it from external interference. Pharmaceutical aluminum foil and PVC/PVDC rigid sheets are the most representative materials in these two core layers, especially in the pharmaceutical field where safety and sealing requirements are extremely high, they are indispensable.

Sealing Layer: Pharmaceutical PTP Aluminum Foil

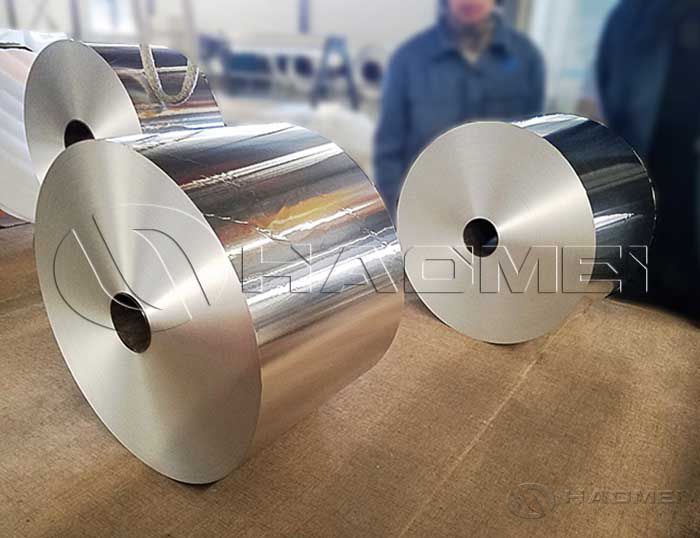

In pharmaceutical blister packaging, the thin silver metallic sheet we tear open is mostly pharmaceutical PTP aluminum foil (Press Through Packaging Foil). It is not a single material, but a multi-layered composite structure, typically consisting of an OP layer, a printed layer, an aluminum foil layer, and a VC layer.

Each layer has a unique function: the OP layer (polyolefin layer) provides surface protection; the printed layer carries key information such as the drug name and batch number; the core aluminum foil layer is responsible for barrier properties; and the VC layer (ethylene-vinyl acetate copolymer) ensures a tight seal with the blister pack.

As a packaging material that comes into direct contact with pharmaceuticals, pharmaceutical aluminum foil has extremely stringent performance requirements. It must possess excellent oxygen barrier, moisture barrier, and contamination resistance capabilities.

Relevant standards stipulate that its vapor permeability and oxygen permeability must both be ≤0.5%, ensuring that the drug is not affected by the external environment during long-term storage.

Simultaneously, it must have just the right amount of "tearability"—it must be able to seal firmly yet allow consumers to easily press and tear it open to remove the drug without effort. This balanced characteristic makes PTP aluminum foil the "standard" material for blister packaging in the pharmaceutical industry.

Besides pharmaceuticals, some high-end food and health product blister packaging also uses pharmaceutical-grade PTP aluminum foil. Leveraging its safety barrier properties, it extends product shelf life and enhances consumer trust.

Blister layer: PVC/PVDC rigid sheet

If PTP aluminum foil is the "safety gatekeeper" of blister packaging, then the pvdc coated pvc film is undoubtedly the "shaping skeleton" and "protective barrier." This material, made through a precision composite process, is the core of the transparent "small bubbles" in pharmaceutical and high-end product blister packaging. It can be precisely shaped with excellent performance while providing reliable protection, perfectly meeting the packaging needs of tablets, capsules, and other products.

PVC/PVDC rigid sheets are not simply a mixture of materials, but a typical "complementary advantage" structure. Commonly, it uses PVC (polyvinyl chloride) as the bottom layer and PVDC (polyvinylidene chloride) as the middle functional layer. Some also add a PE (polyethylene) surface layer to form a multi-layered composite structure.

The bottom PVC layer gives the material excellent thermoforming properties, allowing for rapid shaping on high-speed packaging equipment and precise fit to various product shapes. It also offers good transparency, enabling consumers to clearly observe the product's condition inside, while maintaining relatively controllable costs.

The middle PVDC layer is the "reinforcing core" of barrier performance. Its dense molecular structure effectively isolates oxygen, water vapor, and light, fundamentally delaying the oxidation, moisture absorption, or degradation of pharmaceuticals—an advantage that PVC alone cannot match. If the surface layer contains PE, it further enhances the material's toughness and impact resistance, preventing packaging damage during transportation and storage.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

-

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China