1050 Aluminum Foil for Transformer

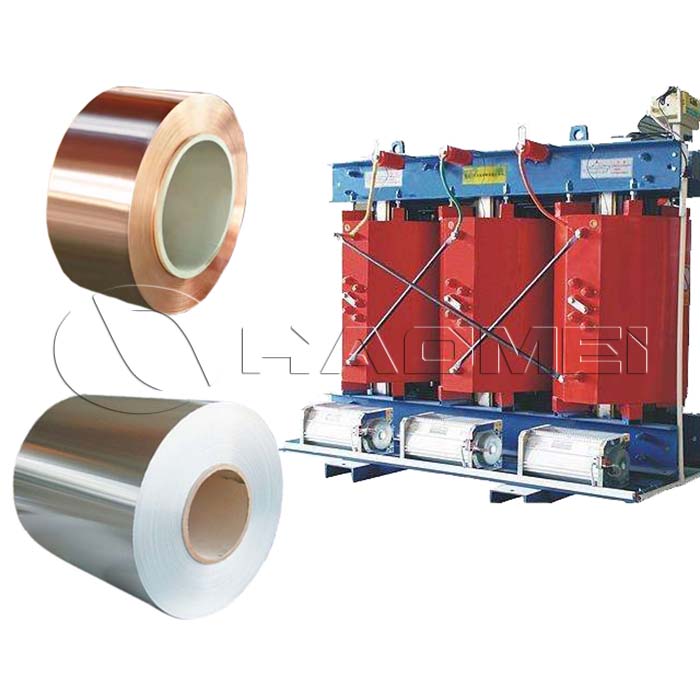

Aluminum foil for transformer is mainly used for dry-type and oil-immersed transformer winding. The material is generally high-purity aluminum 99.65% like 1050 aluminum foil. Learn more.

The winding is one of the most important components of the transformer and is the conductive part of the transformer. The primary winding of the transformer converts electrical energy into magnetic field energy through the iron core, and the secondary winding restores the magnetic field energy into electrical energy through the iron core and outputs it.

There are two main types of layered coils: cylindrical and foil. Foil coils are made of copper foil or aluminum foil for transformer instead of wires. The insulating material and the conductive material are placed together on a special foil winding machine for continuous winding, each layer is one turn, and each layer of copper or aluminum foil is separated by an insulating material.

Foil coils are currently mainly used for low-voltage winding of transformers, and some manufacturers use segmented foil structures to increase the number of turns and use foil winding for high-voltage winding.

Aluminum foil for transformer is mainly used for dry-type and oil-immersed transformer winding. Aluminium foils for transformer winding range from 0.2mm to 3.5mm thickness and 10mm to 1600mm wide. The coil is wound on insulating material such as paper, kraft paper, mylar or glass cloth. Transformer aluminum foil is with high electrical conductivity, good corrosion resistance and beautiful appearance, which is an essential material in the transformer production process.

Haomei Aluminum is specialized in aluminum foil transformer winding, usually this foil is used in coils for transformer winding. The material is generally high-purity aluminum 99.65% like 1050 aluminum foil.

1050 aluminium foil is soft and suitable for winding, 1050 aluminum alloy also has no burrs on the edges, making it safe when laminated with insulating film. The surface is free of oil, scratches, deformation, so that the insulating film can be properly laminated.

Product Name | Aluminium foil for transformer |

Alloys | 1050,1350,1060,1070 |

Temper | O |

Thickness | 0.2-3.5mm |

Width | 10-1600 mm |

Tolerance | ±10% |

Inner diameter | Ø 150mm,Ø300mm, Ø400mm, Ø500mm paper cores;special ID cores; paperless cores; special requirements |

Surface | Smooth surface, free from scratches and impurities |

Conductivity | Transformer windings are guaranteed to be better than 60 % ACS-62.7% ACS under annealed condition |

Application | Transformer winding |

Package | Wooden Pallets/Wooden Boxes |

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

-

Which Medicines Are Packaged in Aluminum Foil Blister Packaging

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China