Aluminum 1050 H14 VS H24

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

As a pure aluminum product, 1050 aluminum foil jumbo roll has an aluminum content exceeding 99.5%, which gives it two core advantages: Firstly, it offers strong corrosion resistance and is resistant to oxidation in humid and weakly acidic environments, making it suitable for applications requiring high hygiene standards such as food and pharmaceuticals; secondly, it exhibits excellent plasticity, making it easy to form complex shapes through processes such as cold rolling and stamping.

1050-H14

Aluminum 1050 h14's core process is "cold rolling + work hardening": 1050 aluminum foil billets are rolled through a cold rolling mill multiple times, utilizing the "work hardening effect" generated by metal deformation to increase the material's hardness and strength, ultimately achieving the performance standard of "1/4 hard".

Core performance

Hardness: Approximately 50-58 HRF (Rockwell hardness), with a noticeably rigid feel and resists manual bending and deformation.

Tensile strength: 110-145 MPa, 15%-50% higher than the soft O state (approximately 95 MPa), capable of withstanding certain external impacts.

Elongation: 8%-15% (50mm gauge length), with moderate formability, capable of simple bending but unable to withstand complex stamping (such as deep drawing or drawing).

Typical applications

Food Packaging: Disposable aluminum foil container, household aluminum foil rolls, etc.

Electronic shielding: Shielding covers for small electronic components (such as the signal shielding layer in routers and headphones, which requires a certain strength to prevent deformation during transportation);

General industrial gaskets: Sealing gaskets for pipes and equipment (no complex design required, only high pressure resistance and resistance to breakage).

1050-H24 aluminum

The H24 process has an additional key step compared to the H14 process: after cold rolling and work hardening, the aluminum foil is placed in an annealing furnace for "low-temperature incomplete annealing." By controlling the temperature (approximately 200-250°C) and time, some internal stresses are eliminated while retaining most of the strength gained from work hardening. The result is the same "quarter-hard" state, but with properties leaning towards "toughness."

Core performances

Hardness: Approximately 48-55 HRF, slightly lower than H14, with a slightly softer feel but still rigid.

Tensile strength: 110-140 MPa, similar to H14, with no significant decrease in strength.

Elongation: 10%-18% (50mm gauge length), 2-3 percentage points higher than H14, allowing it to withstand more complex stretching and stamping processes without cracking or breaking.

Typical applications

Pharmaceutical packaging: Aluminium 1050 h24 is often used for blister packaging (e.g., aluminum-plastic blisters for capsules and tablets, which require punching to form raised cavities; insufficient elongation can easily lead to blister rupture);

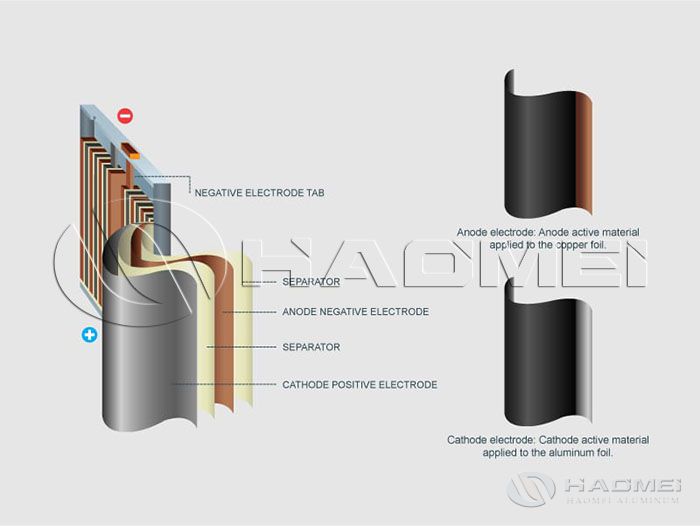

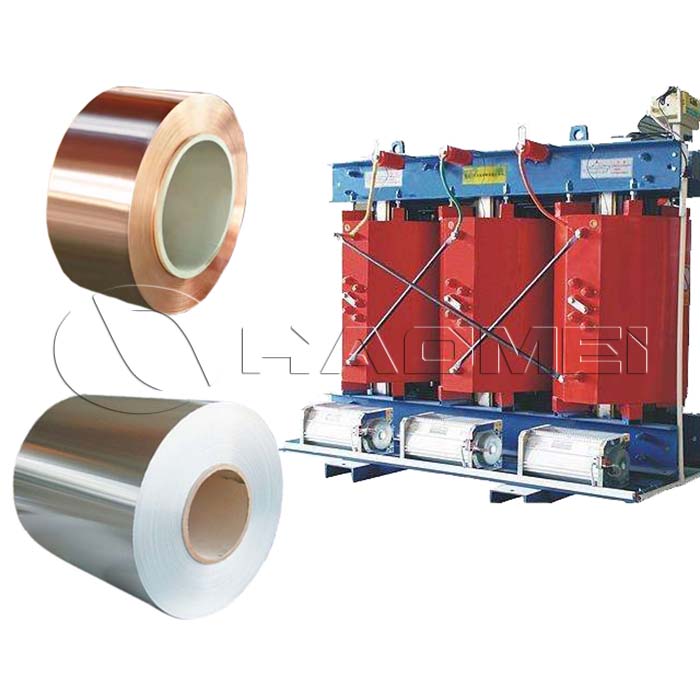

Battery components: Aluminum foil for lithium battery tabs (tabs require multiple bending and welding processes; high elongation reduces the risk of breakage during bending);

Precision hardware: Small aluminum foil components for automotive interiors (e.g., decorative foil for air conditioner vents, which must conform to curved surfaces and maintain shape stability after complex molding).

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

-

Which Medicines Are Packaged in Aluminum Foil Blister Packaging

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

-

What Are Aluminum Foil Uses in the Kitchen?

Food aluminum coil is a versatile kitchen helper like baking, grilling, food preservation and cookware cleaning. How can it help you deal with kitchen problems? Learn more.

Blog

Food aluminum coil is a versatile kitchen helper like baking, grilling, food preservation and cookware cleaning. How can it help you deal with kitchen problems? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China