Aluminum or Tin Foil for Capacitor

Among the core materials of capacitors, the choice of electrode metal foil is particularly crucial. When metal foil is mentioned, many people first think of tin foil, but in the capacitor manufacturing industry, capacitor aluminum foil has long been the a

Among the core materials of capacitors, the choice of electrode metal foil is particularly crucial. When metal foil is mentioned, many people first think of tin foil, but in the capacitor manufacturing industry, capacitor aluminum foil has long been the absolute mainstream due to its unique advantages.

1. Superior Specific Capacitance

Specific capacitance is a core indicator for measuring capacitor electrode materials, representing the capacitance that a unit mass or volume of material can store. After electrochemical etching and other processes, aluminum foil forms a dense porous structure on its surface, greatly increasing the contact area between the electrode and the electrolyte, thus significantly improving its specific capacitance.

In contrast, tin foil has a relatively dense crystal structure, making it difficult to achieve efficient surface activation through conventional processes. Its specific capacitance is typically only 1/3 to 1/5 that of aluminum foil. For modern capacitors that pursue miniaturization and high capacity, this advantage of aluminum foil directly determines the core competitiveness of the product.

2. More Reliable Electrochemical Stability

During the charging and discharging process, the electrodes of a capacitor are in the chemical environment of the electrolyte for a long time; therefore, the electrochemical stability of the material is crucial. Aluminum rapidly forms a dense alumina film in air. This film not only provides excellent insulation but also effectively prevents further corrosion of the aluminum substrate, providing a natural "protective barrier" for the electrodes.

Tin, on the other hand, has relatively high chemical reactivity and readily undergoes redox reactions in electrolytes, leading to a gradual decline in electrode performance and consequently shortening the capacitor's lifespan. Data shows that capacitors using aluminum foil electrodes typically have a cycle life 3 to 10 times longer than those using tin foil electrodes.

3. Superior Processing Performance

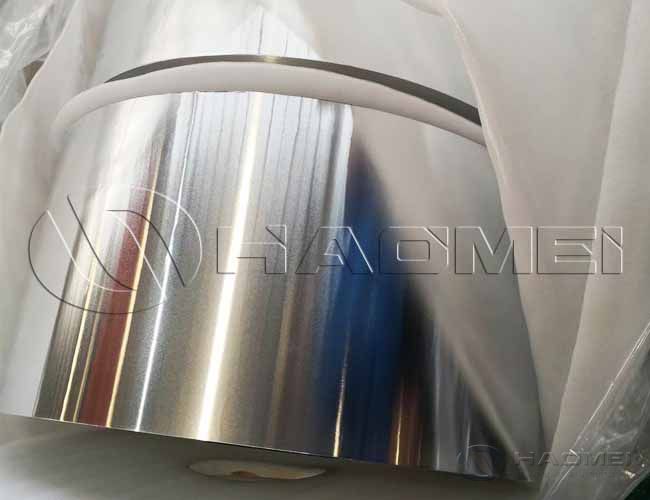

Capacitor metal foil requires multiple precision processing steps, including rolling, slitting, etching, and formation, demanding extremely high processing properties such as ductility and strength. Aluminum foil has excellent ductility, allowing it to be rolled to ultra-thin thicknesses in the micrometer range (down to 0.004 mm) while maintaining good dimensional stability, meeting the production needs of capacitors of various specifications.

While tin foil also possesses some ductility, it is prone to cracking and wrinkling during ultra-thin rolling, resulting in a lower processing yield. Furthermore, aluminum foil offers superior cutting and stamping performance, significantly improving capacitor production efficiency.

4. More Reasonable Cost Control

From a resource reserve perspective, aluminum is one of the most abundant metallic elements in the Earth's crust, with reserves far exceeding tin. This gives aluminum foil a natural advantage in raw material costs. Simultaneously, the mature production process and high output of aluminum foil further reduce unit production costs.

In contrast, tin is a scarce metal, with fluctuating raw material prices and high processing difficulty, resulting in a significantly higher overall cost for tin foil compared to aluminum foil. For capacitor manufacturers producing in bulk, choosing aluminum foil as the electrode material can effectively reduce production costs while ensuring product performance, thereby enhancing market competitiveness.

Capacitor Aluminum Foil Alloys

Capacitor aluminum foil mainly includes 1-series pure aluminum alloys (1060 and 1070), 3-series aluminum alloys (3003 and magnesium-silicon-containing 3-series alloys), 2-series copper-containing aluminum alloys, and high-temperature resistant aluminum alloys containing chromium and zirconium.

1. 1060 and 1070 (1-series pure aluminum foil): Primarily used as the positive electrode foil in aluminum electrolytic capacitors. Its high purity and stable electrochemical performance allow for the formation of a uniform and dense oxide film. It is also suitable for high-frequency circuit capacitors, as its excellent conductivity reduces signal loss.

2. 3003 aluminum foil (3-series aluminum alloy foil containing manganese): The preferred choice for the negative electrode foil in aluminum electrolytic capacitors. Manganese enhances corrosion resistance and optimizes surface corrosion, resulting in a porous structure that significantly improves electrode specific capacitance, meeting the high capacitance requirements of negative electrode foil.

3. 2-series aluminum alloy foil containing copper: Mainly used for film capacitor electrodes. Copper balances conductivity and mechanical strength, solving the strength problem of insufficient pure aluminum foil and meeting the dual requirements of film capacitors for electrodes with "high strength and excellent conductivity."

4. High-temperature resistant aluminum alloy foil containing chromium and zirconium: Suitable for capacitors in high-temperature environments such as automotive electronics and industrial control equipment. Chromium and zirconium enhance thermal stability, ensuring that the electrode maintains stable electrochemical performance and structural integrity under high-temperature conditions.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

-

Which Medicines Are Packaged in Aluminum Foil Blister Packaging

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

-

What Are Aluminum Foil Uses in the Kitchen?

Food aluminum coil is a versatile kitchen helper like baking, grilling, food preservation and cookware cleaning. How can it help you deal with kitchen problems? Learn more.

Blog

Food aluminum coil is a versatile kitchen helper like baking, grilling, food preservation and cookware cleaning. How can it help you deal with kitchen problems? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China