How to Control Thickness Difference of Heavy Duty Foil

From heavy duty foil to light gauge foil, the aluminum foil paper is of wide application. How to control its thickness difference? Learn more.

From heavy duty foil to light gauge foil, the aluminum foil paper is of wide application including household foil, container foil, food foil, flexible packaging foil, beer sealing foils, medicinal foils, cigarette foils, hairdressing foils, decorative foils for interior walls. How to control its thickness difference? Lets come to know its rolling production system first.

Rolling is a metal processing method that changes the cross-sectional shape and size of the metal between the rotating rolls of the rolling mill, while controlling its microstructure and properties. Steel, non-ferrous metals, some rare metals and their alloys can all be processed by rolling.

In addition to changing the shape and size of the metal, rolling can also improve the initial as-cast structure of ingots and continuous casting billets, refine grains, and improve the composition and distribution of phases, thus improving product performance.

According to the configuration and rotation direction of the rolls, the movement of the rolling stock and the shape of the product, the rolling methods mainly include longitudinal rolling, cross rolling and skew rolling. According to the degree of work hardening, recovery and recrystallization of the metal during the rolling process, rolling is divided into hot rolling, cold rolling and warm rolling.

According to the different types of rolling products, rolling can be divided into billet rolling (preliminary rolling), strip and foil rolling (strip and foil production), profile and wire rolling (profile and wire production), pipe rolling (pipe production) and the rolling of special shapes such as periodic section rolling,etc.

Difficulty control of thickness error is a feature of aluminum foil rolling. The thickness difference of 3% is not difficult to control in the production of aluminium sheet and strip, but it is more difficult to control in the production of aluminum foil. As the thickness of the aluminum alloy product decreases, many trace conditions can affect it such as temperature, oil film, and oil and gas concentration.

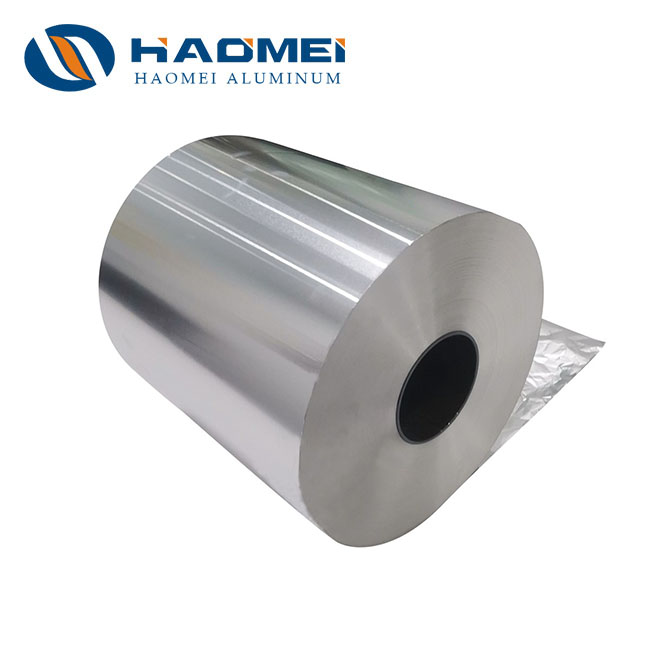

A roll of aluminum foil can be rolled up to hundreds of thousands of meters, and the rolling time is about 10 hours. It is easy to form errors in thickness measurement over time. The only way to adjust the thickness of aluminum foil is tension and speed. These factors all cause the difficulty of thickness control in aluminum foil rolling.

Therefore, to really control the thickness difference of the aluminum foil within 3% need many conditions like using aluminum foil blanks of qualified thickness, adjusting and controlling the reduction and roll shape during rolling, grinding the rolls according to regular parameters, stabilizing the rolling process and frequently measuring the thickness of the aluminum foil during the rolling process.

As a thick aluminum foil supplier, Haomei Aluminum has a strict control of thickness difference within 3%. Rich alloys and excellent performance make haomei aluminium foil jumbo roll a good choice for many customers. Welcome to leave message below to inquire its price.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

-

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China