Is It Economic to Use Aluminum Foil for Making Food Container

The aluminum foil roll for making food container features safety, direct heating convenience and 100% recycle. 8011, 3003, 3004 and 5052 aluminum alloy are all used. Learn more.

In the fast-paced modern life, takeaway and ready-to-eat food have become an important part of daily consumption. However, traditional plastic lunch boxes are gradually being replaced by new materials due to controversy over safety and environmental protection. Aluminum food containers quietly become a rising star in the field of catering packaging with their unique performance advantages.

The core advantage of aluminum foil tray comes from the natural safety of its raw materials. Compared with the risk of plastic lunch boxes releasing harmful substances above 65 ℃, aluminium foil roll has a melting point of up to 660 ℃ and can withstand a variety of heating methods such as ovens and steamers without chemical changes.

The characteristics of different aluminum alloys give food containers a variety of practical functions:

3003 aluminum foil has medium strength and ductility, and can be stamped into complex shapes without cracking. It can resist the penetration of soup with coating technology. This aluminum-manganese alloy has good corrosion resistance and plasticity. The dense oxide layer formed naturally on its surface can effectively block the precipitation of aluminum ions, ensuring the safety of contact with food in normal acid and alkali environments.

3004 aluminum foil improves hardness while maintaining ductility by adding 1% magnesium, which is suitable for food container designs with higher requirements for mechanical properties.

As a typical packaging foil, 8011 aluminum foil enhances barrier properties through surface treatment and prolongs the shelf life of food, which is especially suitable for perishable products such as cakes and seafood.

8006 aluminum foil optimizes the iron-silicon content to ensure thermal conductivity while reducing costs, making it an ideal choice for economical aluminum foil food container.

As a representative of aluminum-magnesium alloy, 5052 aluminum foil jumbo roll improves strength and corrosion resistance by optimizing magnesium content, and is particularly suitable for large-capacity lunch boxes that require structural support.

The thickness of these alloys is usually controlled between 0.03-0.2mm, which not only ensures high thermal conductivity for fast and uniform heating, but also meets the requirements of lightweight.

The environmental value of aluminum foil container is reflected in the entire life cycle. The production process uses cold rolling technology to reduce energy consumption, which is lower carbon than traditional injection molding. After use, container aluminum foil can be 100% recycled, and the recycling energy consumption is only 5% of the original aluminum, and the number of cycles is unlimited. Data shows that the recycling rate of aluminum is as high as 95%, making it one of the most sustainable choices in food packaging.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

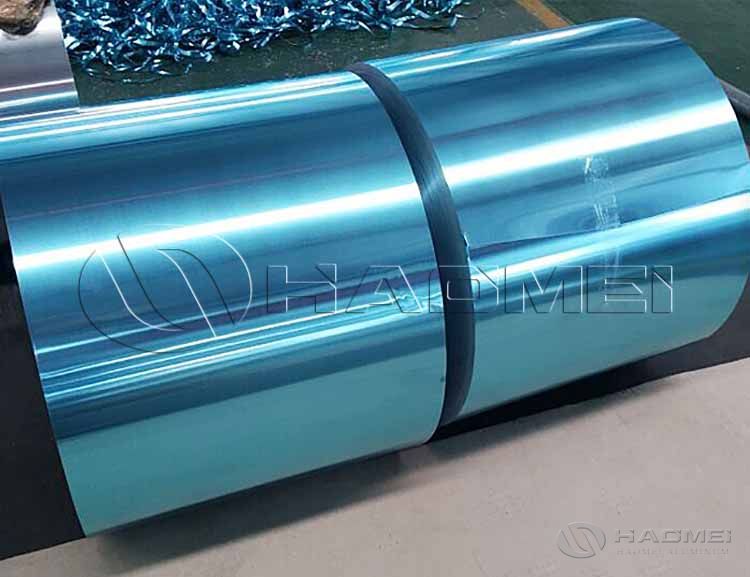

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

-

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China