What Are Alloys of Aluminum Foil Battery

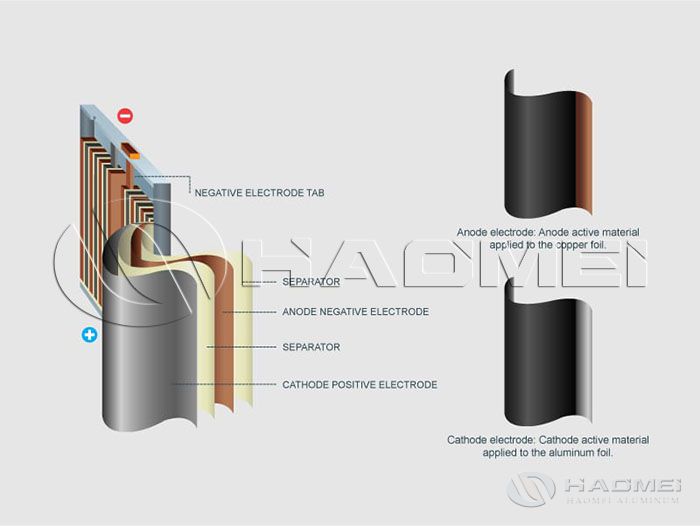

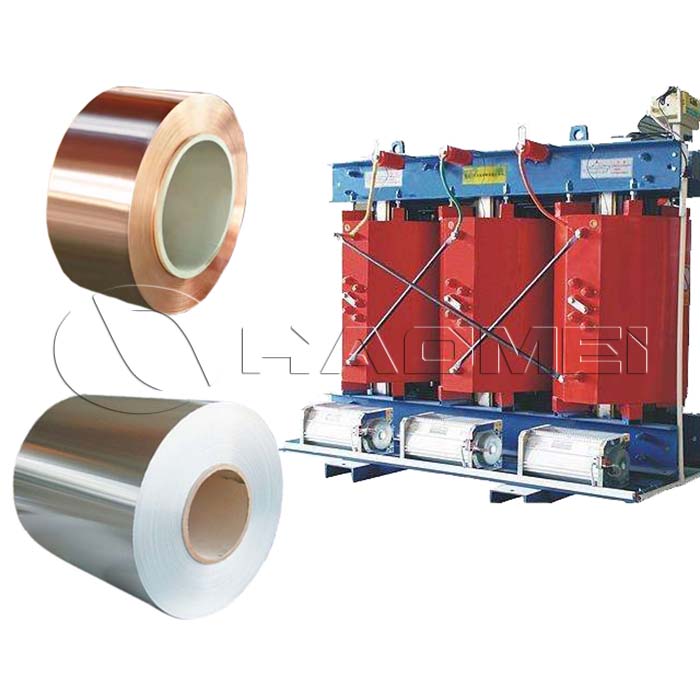

The alloys of battery aluminum foil have three series:1000 series, 8000 series and composite materials. Haomei Aluminum mainly provides 1000 series like 1100 aluminum foil. Learn more.

The current technical level of aluminum foil battery has entered the "ultra-thin, high-precision" stage. The thickness of mainstream power battery aluminum foil is concentrated in 12-16 microns (μm), while the consumer electronics field has achieved a breakthrough of 6-9μm.

In terms of performance indicators, the tensile strength of 15μm aluminum foil jumbo roll can reach 200-210MPa, the elongation is 1.5%-4.0%, the surface roughness is controlled at Ra≤0.3μm, and the pinhole density is ≤0.5/m².

The alloy selection of battery aluminum foil needs to take into account conductivity, corrosion resistance and processing performance. Currently, three major mainstream systems have been formed:

8 series alloys (8011/8021/8079)

8011: Contains 0.8% Fe+Si, has both cost and performance advantages, is widely used in consumer electronics and energy storage batteries, and has a thickness range of 10-20μm.

8021: The Fe content is increased to 1.0%-1.5%, and the corrosion resistance is enhanced. It has become the first choice for soft-pack battery aluminum-plastic film, and the thickness can reach 0.02-0.5mm.

8079: Add 0.8% Zn, higher strength (tensile strength ≥220MPa), used for high-rate power batteries.

1 Series Pure Aluminum (1100/1235)

1100 aluminum foil: 99.0% purity, excellent conductivity (conductivity ≥ 62% IACS), but low strength (tensile strength 150-180MPa), suitable for weight-sensitive power batteries.

1235: 99.35% purity, elongation up to 5%, commonly used in carbon-coated aluminum foil for energy storage batteries.

Composite current collector

By depositing a metal layer on the PET substrate through the evaporation process, the battery energy density is increased by 20% and the risk of thermal runaway is reduced by 90%.

It is worth noting that energy storage batteries have higher requirements for the high temperature resistance of aluminum foil, and usually need to pass the 180℃/2 hour baking test. Power batteries are more concerned about thickness tolerance (±0.3μm) and density consistency (±0.85g/m²).

Market structure and future trends

Capacity and demand

The global demand for battery aluminum foil is expected to reach 600,000-1 million tons in 2025, but the actual production capacity is only 737,600 tons due to the low yield rate (average 60%), with a gap of 257,900 tons. China accounts for 70% of the global production capacity.

Technology iteration direction

Thinner: The demand for aluminum foil below 10μm will increase from 10% in 2023 to 20% in 2025, but it will put forward higher requirements for rolling mill precision and process control.

Compounding: Composite aluminum foil is expected to achieve large-scale mass production in 2025, and the localization of evaporation equipment will drive costs down by 30%.

Functionalization: Graphene-coated aluminum foil can improve the low-temperature performance of batteries (-20℃ discharge capacity retention rate ≥85%), while fluorocarbon spraying technology enhances corrosion resistance.

Haomei Aluminum mainly provides 1xxx battery aluminum foil like 1100, 1235, 1060, 1070,etc. Welcome to inquire what you need from us.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

-

Which Medicines Are Packaged in Aluminum Foil Blister Packaging

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China