What Is The Market Prospect of Battery Hack Aluminum Foil

The demand for lithium battery aluminum foil like battery hack aluminum foil is driven by power batteries, 3C batteries and energy storage batteries. How about its market prospect? Learn more.

According to GGII statistics, the global sales of new energy vehicles in the first half of 2021 were 2.252 million, an increase of 151%, and the installed capacity of power batteries was about 100.49GWh, an increase of 141%.

New energy vehicles drive power batteries to grow rapidly. It is estimated that the global sales of new energy vehicles will exceed 5 million in 2021, driving the installed capacity of power batteries to exceed 250GWh.

As the main technical route of electrochemical energy storage, lithium-ion energy storage batteries have the characteristics of high energy density, high comprehensive efficiency, great potential for cost reduction, short construction period and wide applicability, etc.

We expect lithium battery shipments to reach 1,135.4GWh, including 873.6GWh of power batteries, 94.3GWh of 3C digital batteries, and 167.5GWh of energy storage batteries. Correspondingly, the demand for battery hack aluminum foil in 2025 will reach 454,200 tons to 681,200 tons.

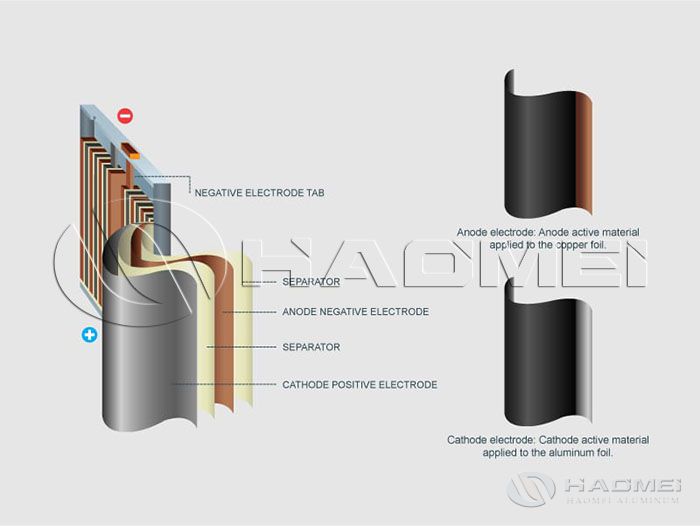

Similar to the lithium battery copper foil, the battery aluminum foil is the key material for the current collector of the lithium battery cathode material. Its main function is to collect the current generated by the battery active material and output the current. In order to obtain a lithium battery with better performance, it is required that the conductive current collector should be in full contact with the active material, and the internal resistance should be as small as possible.

Due to its good electrical conductivity, soft texture, mature manufacturing technology, and outstanding cost advantages, aluminum foil has become the first choice for lithium-ion battery cathode current collectors. At present, the thickness of the current collector aluminum foil of lithium battery is 9-20 μm.

The battery aluminum foil is used as the current collector of lithium ion batteries. The use of this type of aluminum foil can greatly reduce the contact resistance between the positive/negative electrode material and the current collector, and improve the adhesion between the two, thereby significantly improving the battery life of pure electric vehicles and hybrid vehicles.

As the energy density of the power battery increases, the thickness of the aluminum foil as the current collector is getting thinner and thinner, and the production requirements are higher.

Generally speaking, the strength requirement is inversely proportional to the thickness, and the battery foil needs to increase the strength in order to reduce the thickness of the aluminum foil and provide conditions for increasing the energy density. Most battery hack aluminum foil customers require the thickness standard of aluminum foil products to be in the range of ±2%.

At present, most of the online thickness control systems of aluminum foil rolling mills are difficult to meet this requirement. This thickness accuracy requirement is the highest among all aluminum foil products at present, and the process barrier is relatively high. Generally speaking, the technological difficulty of battery foil is reflected in thickness requirements, thickness accuracy requirements, strength, surface dyne value, etc.

As a big aluminum foil sheet manufacturer, Haomei Aluminum can reach a balance between the thinnest thickness, the highest strength, the highest dyne value, the smallest thickness difference, the best shape and the cleanest surface. Welcome to leave message below to inquire what you need.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

-

Which Medicines Are Packaged in Aluminum Foil Blister Packaging

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China