The Use of Aluminum Foil in Industrial Field

Among the many materials used in industrial production, aluminum foil plays an indispensable role in several key areas due to its unique physicochemical properties.CapacitorsAs crucial components for storing charge in electronic circuits, capacitors are w

Among the many materials used in industrial production, aluminum foil plays an indispensable role in several key areas due to its unique physicochemical properties.

Capacitors

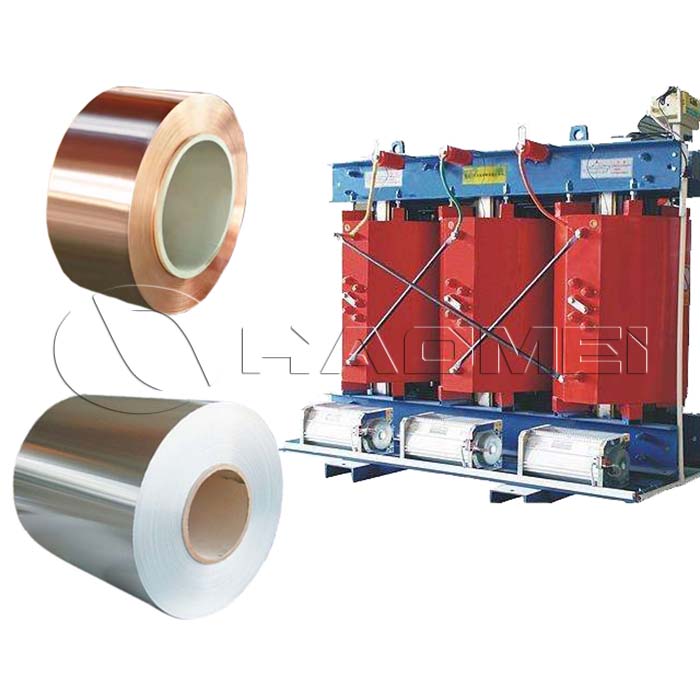

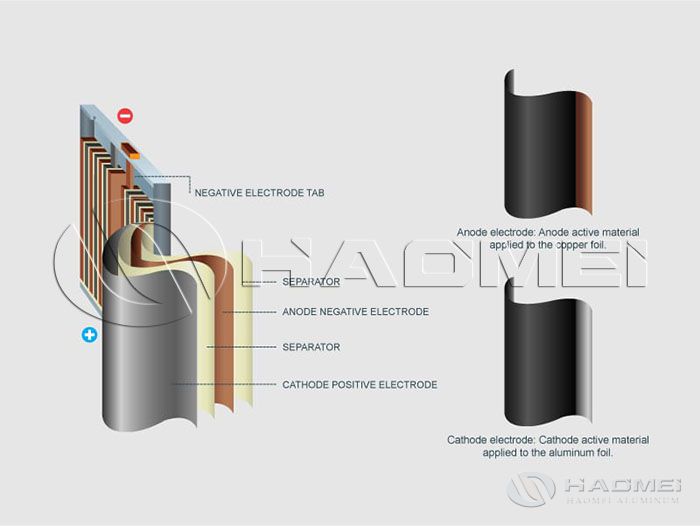

As crucial components for storing charge in electronic circuits, capacitors are widely used in home appliances, automotive electronics, and new energy equipment. Aluminum foil is one of the core materials inside capacitors, primarily functioning as electrode foil.

The key to aluminum foil's ideal choice as an electrode in capacitor structures lies in its ability to form a porous structure through an etching process. After special etching treatment, the surface area of the aluminum foil increases significantly, effectively creating more "storage space" for charge and significantly improving the capacitor's capacitance.

Simultaneously, the excellent conductivity of capacitor aluminum foil ensures rapid charge transfer between electrodes, reducing energy loss and allowing the capacitor to maintain efficient and stable performance during charging and discharging.

Furthermore, aluminum foil possesses excellent oxidation properties. During capacitor manufacturing, a dense oxide film (aluminum oxide) forms on the surface of the aluminum foil. This oxide film has excellent insulation properties, effectively isolating the positive and negative electrodes, preventing charge leakage, and ensuring the capacitor's lifespan and safety.

Currently, with the rapid development of industries such as new energy vehicles and 5G communications, the performance requirements for capacitors are becoming increasingly stringent. High-purity, high-specific-surface-area aluminum foil has thus become a key research focus, further promoting its upgraded application in the electronics industry.

Ventilation Ducts

In ventilation systems of industries such as construction, chemical processing, and food processing, aluminum foil is also an important supporting material, mainly used for insulation, moisture protection, and sealing of ventilation ducts, ensuring efficient air transport.

From an insulation perspective, aluminum foil has a low thermal conductivity and a smooth surface that effectively reflects heat. Combining it with insulation materials such as glass wool and rock wool to create composite ventilation ducts reduces heat exchange between the air inside the duct and the external environment, ensuring stable air temperature (for example, in air conditioning systems, preventing temperature loss of cold or hot air during transmission), while also reducing energy consumption, meeting the energy-saving requirements of the industrial sector.

In terms of moisture resistance and corrosion resistance, aluminum foil possesses excellent chemical stability, rarely reacting with water or moisture. Using it as the outer or inner layer material of ventilation ducts effectively isolates external moisture and corrosive gases from entering the ductwork, preventing rust or corrosion of the inner walls due to moisture, thus extending the service life of the ventilation ducts.

It also ensures the cleanliness of the transported air, preventing impurities from entering the air and affecting the production environment due to duct damage (especially in industries with high air cleanliness requirements, such as food processing and pharmaceutical manufacturing).

Furthermore, the lightweight and easy-to-process nature of aluminum foil duct facilitates the fabrication and installation of ventilation ducts. Compared to traditional metal duct materials, aluminum foil composite ducts are lighter, saving manpower and time costs during transportation and installation. They can also be cut into different sizes and shapes to suit various complex industrial plant layouts.

Besides its core applications in capacitors and ventilation ducts, aluminum foil, with its diverse properties, plays an important role in packaging, printing, aerospace, and other industrial fields. For example, in industrial product packaging, aluminum foil can be used for moisture-proof and oxidation-proof sealed packaging; in the aerospace field, high-purity aluminum foil can be used to manufacture lightweight parts.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China